Overview:

This patented project took two years to develop. I designed the protocol to 3D scan a head and produce a custom fit helmet for an individual. The key to this concept was to negotiate with the standards bodies to allow individual helmets to be certified without the need of going through destructive testing.

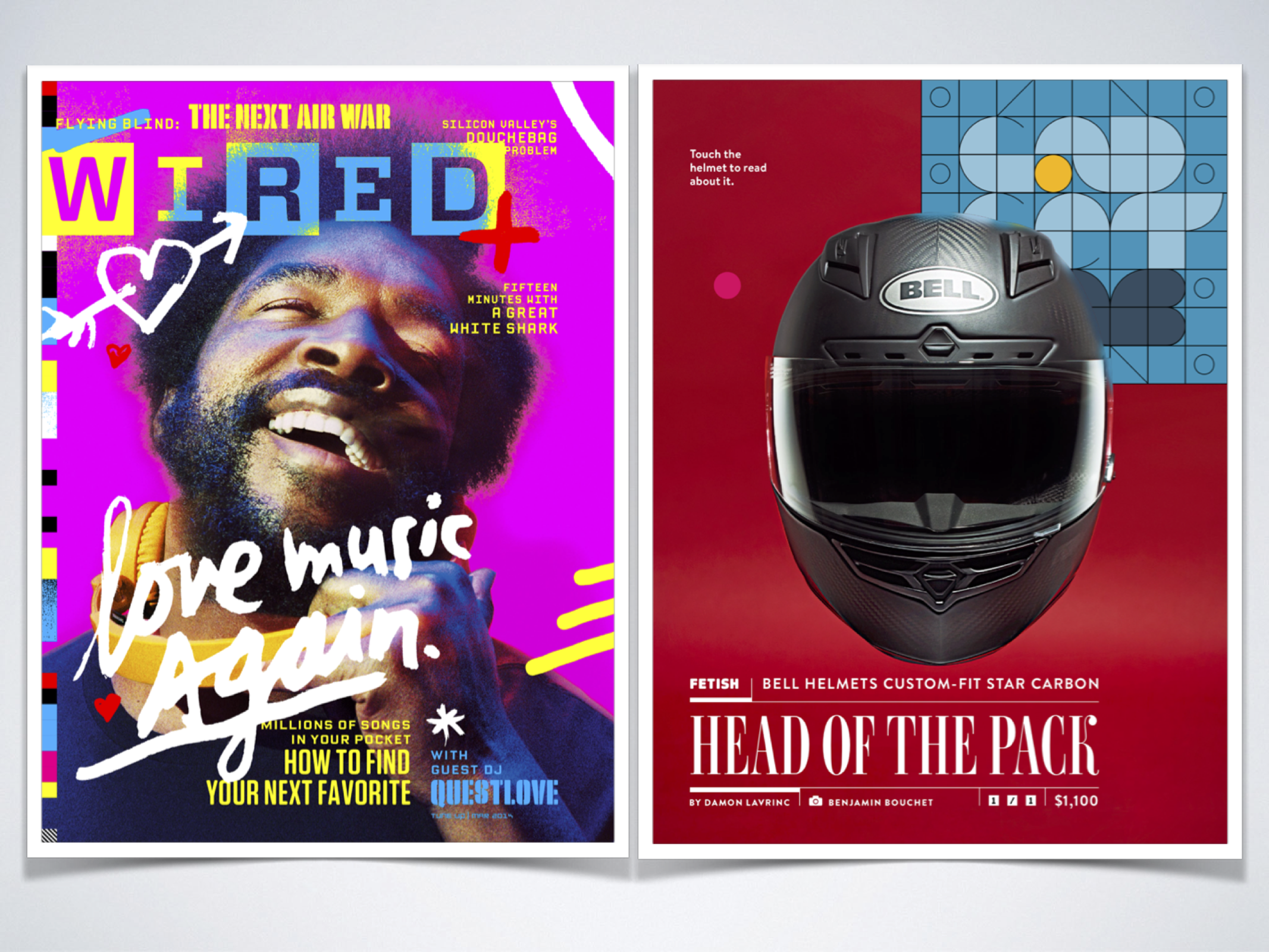

It was featured in Wired magazine.

This technology is now being used by Bell, Giro and Riddell to make custom fit helmets.

Case Study:

The impetus for this project was to give access of the advanced technology of producing custom fitted helmets from the professional level to the general consumer. We had made one off helmets for professional athletes for years using a large and expensive white light scanner.

The first challenge was the scanner was difficult to travel with and in addition required a fast computer to process the data to create the 3D scan point cloud. This meant we either flew to the athlete with all of our equipment or had the athlete come to us.

The second challenge was every custom helmet needed to be certified to an impact standard. This required the manufacture of at least 5 of each custom helmet, send them to the certifying body for impact testing which took time and money.

To start I researched the current state of 3D scanners at the time. I found and experimented with many different styles but most were too expensive or had limitations on resolution. I then read an article about the Microsoft advanced concepts experimenting with their Kinect scanner. The same technology used in the X-Box games for motion control. They were using their scanner to capture room dimensions and distances. I purchased a Kinect scanner and began searching the web for information on using the point cloud data it created to detect motion. From there I started experimenting with acquiring scans of my head and processing the point cloud data into something I could use in Solidworks.

Once I established a clean process for the scan acquisition I then set out to create a protocol where we could use the scan data to build a custom helmet. This meant finding a way to build a helmet which satisfied the certification requirements. I worked with and negotiated with the SNELL, DOT, CPSC and CE test labs to ensure we could produce one helmet per customer without the need to send in a certification for each.

I then found a group of motorcycle track racers to field test the program and give feedback to fit and function prior to going live. This proved vital as we were able to find flaws in the fit and readjusted prior to launch.